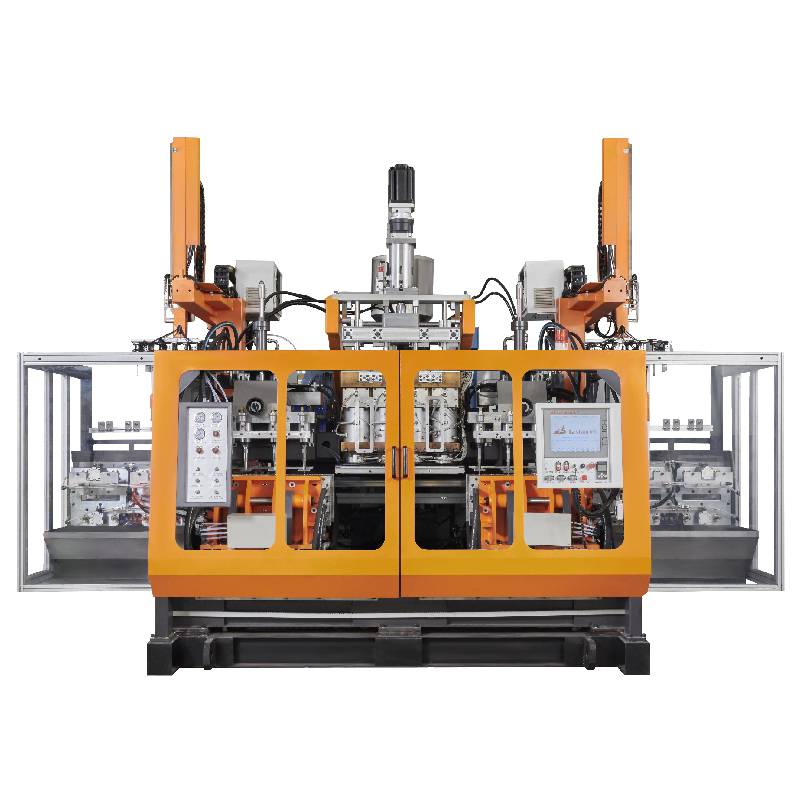

Athlon High Speed blow molding machine

Designed in German, the brand new Athlon Series extrusion blow molding machine is exceeding even more. Equipped with the new designed clamping unit, the machines can run more smoothly and faster. More importantly, the RCI(Rapid Cooling Installation) ensures lower cycle time and higher production capacity. Besides, the machine is designed for the sake of workers. The quick mold change system and external machine adjustment not only increase the production efficiency but also protect the workers’ safety.

✓Single/Double Station

✓Single/Double/Triple/Quadruple..8 Head

✓Production Volume:2ml~30L

✓Multi layers: Co-Extrusion 1-6 Layers

✓Multi cavities: 1~8 cavities

✓Designed for the PE/PP/PETG/PVC/Co-Extrusion material

Category:

Athlon High Speed blow molding machine

Tag:

Leshan Athlon High Speed blow molding machine

Athlon High Speed Hydraulic Extrusion Blow Molding Machine

1.German Design Die with front adjustment for Faster Color Changing and Operators’ Safety

2.Die with Servo Balance System

3.Linear Rail Directive Blowing Pin with Fast Cooling System for Higher Accuracy and Less Friction.

4.RCI(Rapid Cooling Installation) Exchanges the Hot and Cold Air at the Same Time to Increase the Speed by 30%-40%.

5.Electronic Ruler Controlled Clamping Unit for Higher Accuracy and Speed.

6.Quick Mold Changing Design.

7.Optimized Integrated Pipeline Layout Ensures the Oil and Water Leakage Reduce.

Application

Ball

Bath&Beauty

Beverage Package

Car Supplies

Civil Barrel

Jerry Can

Large-volume Tank

Milk Bottle

Toy

Washing Detergent

Other Type

| EXTRUDER | ||||||||

| Extruder Diameter | mm | 45 | 55 | 65 | 75 | 85 | 90 | 100 |

| Extruder Length/Diameter Ratio | L/D | 21 | 23 | 24 | 24 | 24 | 24 | 27 |

| Extruder Rotating Speed | r/min | 20-40 | 20-40 | 10~48 | 20-78 | 20~67 | 20-66 | 20~66 |

| Max Extrusion Capacity | kg/h | 14 | 25 | 30 | 100 | 130 | 160 | 230/280 |

| Extruder Motor Rated Power | kW | 5.5 | 7.5 | 15 | 30 | 37 | 37 | 75/90 |

| Barrel Heating Zone | / | 3 | 3 | 3 | 3 | 3 | 4 | 4 |

| Barrel Heating Power | kW | 4.5 | 6.2 | 7.2 | 10 | 10.4 | 17 | 17 |

| Cooling Fan Power | kW | 0.04 | 0.08 | 0.12 | 0.3 | 0.54 | 0.72 | 1.85 |

| Die Head | ||

| Cavity number | 1-8 | |

| Center Distance | mm | 80-280 |

| MOLD PLATEN | 500 | 650 | 256 | |

| Min Clamping Distance Of Mold | mm | 230 | 230 | 230 |

| Max Clamping Distance Of Mold | mm | 480 | 480 | 480 |

| Effective Dimension Of Mold Plate | mm W×H | 380X465 | 615X505 | 750X465 |

| Carriage Stroke | (mm) | 500 | 650 | 900 |

| Clamping Force | kN | 165 | 256 | 256 |