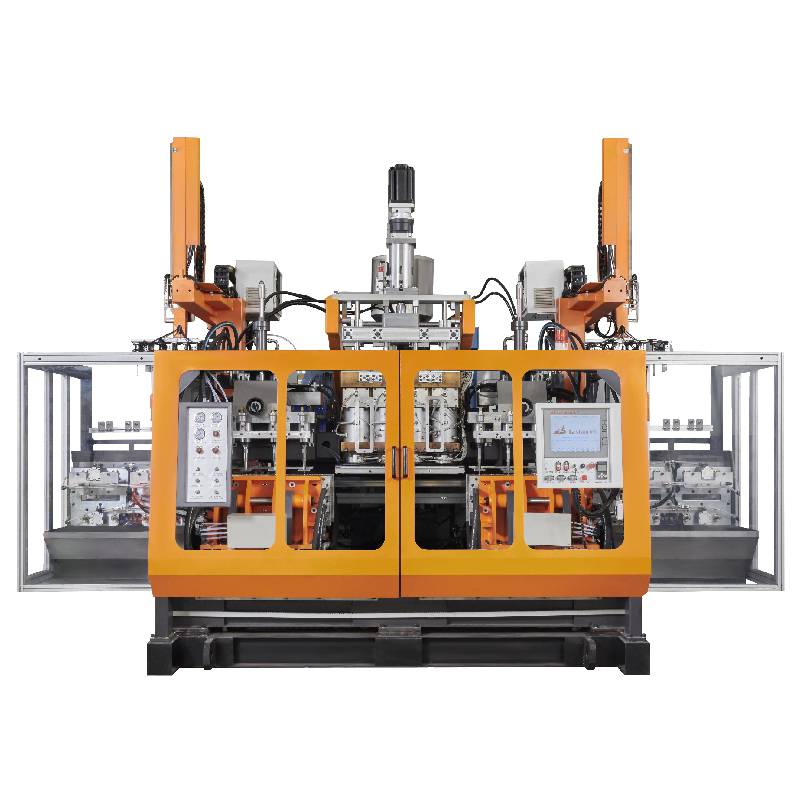

K Economic Hydraulic Blow Molding Machine

Leshan K series extrusion blow-molding machine is the most budget-friendly product. Although after years of technological upgrades, it still occupies a position in the market with high-level performance. The mold locking system of K series consists of 4-guide-pillar structure and 3-plate pulling structure, which can not only hold super-wide and super-long molds but also provides enough locking force. It can produce plastic bottles of various shapes such as milk bottles, cosmetic bottles, jerry can, ocean balls and etc.

✓Single/Double Station

✓Single/Double/Triple/Quadruple..8 Head

✓Production Volume:2ml~20L

✓Multi layers: Co-Extrusion 1-4 Layers

✓Multi cavities: 1~8 cavities

✓Designed for the PE/PP/PETG/PVC/Co-Extrusion material

Category:

K Economic Hydraulic blow molding machine

Tag:

Leshan K Economic Hydraulic Blow Molding Machine

Leshan K Economic Hydraulic Blow Molding Machine

1.Tie-bar Design Clamping Unit which is Suitable for Bulky Mold.

2.Equipped with Clamping Plate Deceleration Valve Device fir Stable Performance and Low Energy Consumption.

3.Air Head Lifting for Smooth Movement.

4.Fast Cooling Exhaust Component Device.

5.Automatic Lubrication System.

6.Auto Empty Hopper Alarm Device.

7.Siemens User-Friendly PLC.

Application

Ball

Bath&Beauty

Beverage Package

Car Supplies

Civil Barrel

Jerry Can

Large-volume Tank

Milk Bottle

Toy

Washing Detergent

Other Type

| EXTRUDER | ||||||||

| Extruder Diameter | mm | 45 | 55 | 65 | 75 | 85 | 90 | 100 |

| Extruder Length/Diameter Ratio | L/D | 21 | 23 | 24 | 24 | 24 | 24 | 27 |

| Extruder Rotating Speed | r/min | 20-40 | 20-40 | 10~48 | 20-78 | 20~67 | 20-66 | 20~66 |

| Max Extrusion Capacity | kg/h | 14 | 25 | 30 | 100 | 130 | 160 | 230/280 |

| Extruder Motor Rated Power | kW | 5.5 | 7.5 | 15 | 30 | 37 | 37 | 75/90 |

| Barrel Heating Zone | / | 3 | 3 | 3 | 3 | 3 | 4 | 4 |

| Barrel Heating Power | kW | 4.5 | 6.2 | 7.2 | 10 | 10.4 | 17 | 17 |

| Cooling Fan Power | kW | 0.04 | 0.08 | 0.12 | 0.3 | 0.54 | 0.72 | 1.85 |

| Die Head | ||

| Cavity number | 1-8 | |

| Center Distance | mm | 80-200 |

| MOLD PLATEN | 2D | 5D | 10D | |

| Min Clamping Distance Of Mold | mm | 130 | 200 | 230 |

| Max Clamping Distance Of Mold | mm | 330 | 450 | 580 |

| Effective Dimension Of Mold Plate | mm W×H | 250×320 | 300×400 | 380×460 |

| Carriage Stroke | (mm) | 400 | 450 | 500 |

| Clamping Force | kN | 27 | 43 | 100 |