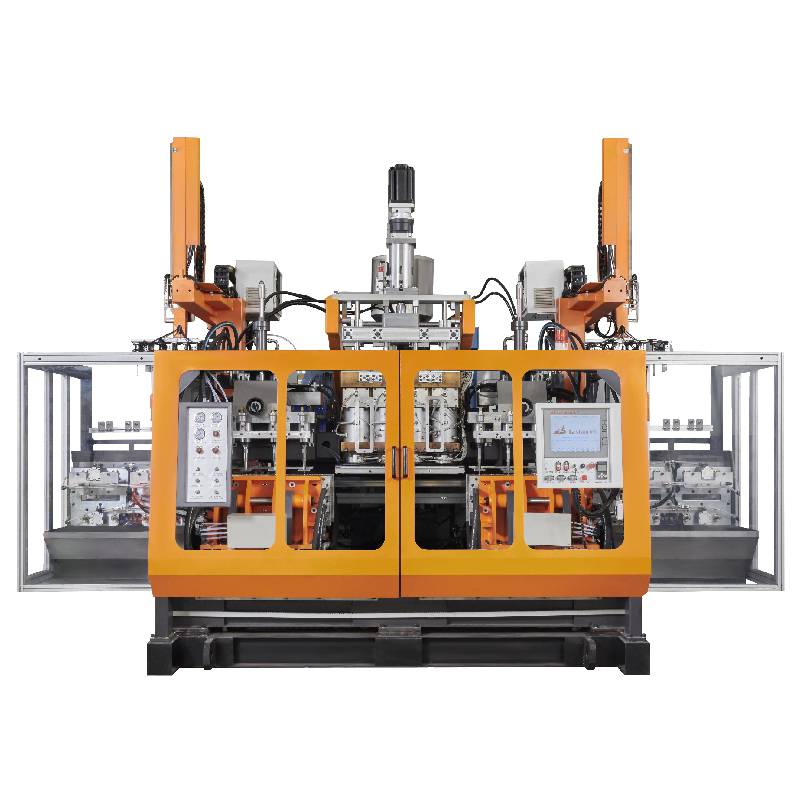

Samp Full Electric Blow Molding Machine

Leshan Samp extrusion blow-molding machine is of more energy saving and higher accuracy. All parts of the eco-friendly Samp extrusion blow-molding machine is full-electric controlled, which means lower energy consumption. Smaller motor makes bigger power. Lower costs barter high efficiency. In addition, controlled by electric motor, the Samp extrusion blow-molding machine functions more accurately and precisely.

✓Single/Double Station

✓Single/Double/Triple/Quadruple..8 Head

✓Production Volume:2ml~30L

✓Multi layers: Co-Extrusion 1-6 Layers

✓Multi cavities: 1~8 cavities

✓Designed for the PE/PP/PETG/PVC/Co-Extrusion material

Category:

Samp Full Electric blow molding machine

Tag:

Samp Full Electric blow molding machine

Leshan Samp Full Electric Blow Molding Machine

1.Electronic Clamping Frame Adopts the Eccentric Gear Structure with Lower Energy Consumption and Quciker Response.

2.Linear Rail Electronic Blowing Pin Greatly Increases the Accuracy.

3.Servo Electronic Head Lifting with High Accuracy and Smooth Performance.

4.Optimized Die Head Flow Path for Fast Color Changing.

5.Electronic Carriage adopts Rack and Gear Structure to Ensure the Accuracy, Lower Energy Consumption and Quicker Response.

Application

Ball

Bath&Beauty

Beverage Package

Car Supplies

Civil Barrel

Jerry Can

Large-volume Tank

Milk Bottle

Toy

Washing Detergent

Other Type

| EXTRUDER | ||||||||

| Extruder Diameter | mm | 45 | 55 | 65 | 75 | 85 | 90 | 100 |

| Extruder Length/Diameter Ratio | L/D | 21 | 23 | 24 | 24 | 24 | 24 | 27 |

| Extruder Rotating Speed | r/min | 20-40 | 20-40 | 10~48 | 20-78 | 20~67 | 20-66 | 20~66 |

| Max Extrusion Capacity | kg/h | 14 | 25 | 30 | 100 | 130 | 160 | 230/280 |

| Extruder Motor Rated Power | kW | 5.5 | 7.5 | 15 | 30 | 37 | 37 | 75/90 |

| Barrel Heating Zone | / | 3 | 3 | 3 | 3 | 3 | 4 | 4 |

| Barrel Heating Power | kW | 4.5 | 6.2 | 7.2 | 10 | 10.4 | 17 | 17 |

| Cooling Fan Power | kW | 0.04 | 0.08 | 0.12 | 0.3 | 0.54 | 0.72 | 1.85 |

| Die Head | ||

| Cavity number | 1-8 | |

| Twin Cavity Center Distance | mm | 80-280 |

| MOLD PLATEN | 200 | 250 | 400 | |

| Min Clamping Distance Of Mold | mm | 250 | 250 | 500 |

| Max Clamping Distance Of Mold | mm | 460 | 510 | 950 |

| Effective Dimension Of Mold Plate | mm W×H | 600X345 | 692X490 | 600X700 |

| Carriage Stroke | (mm) | 750 | 750 | 900 |

| Clamping Force | kN | >=98 | 240 | 280 |