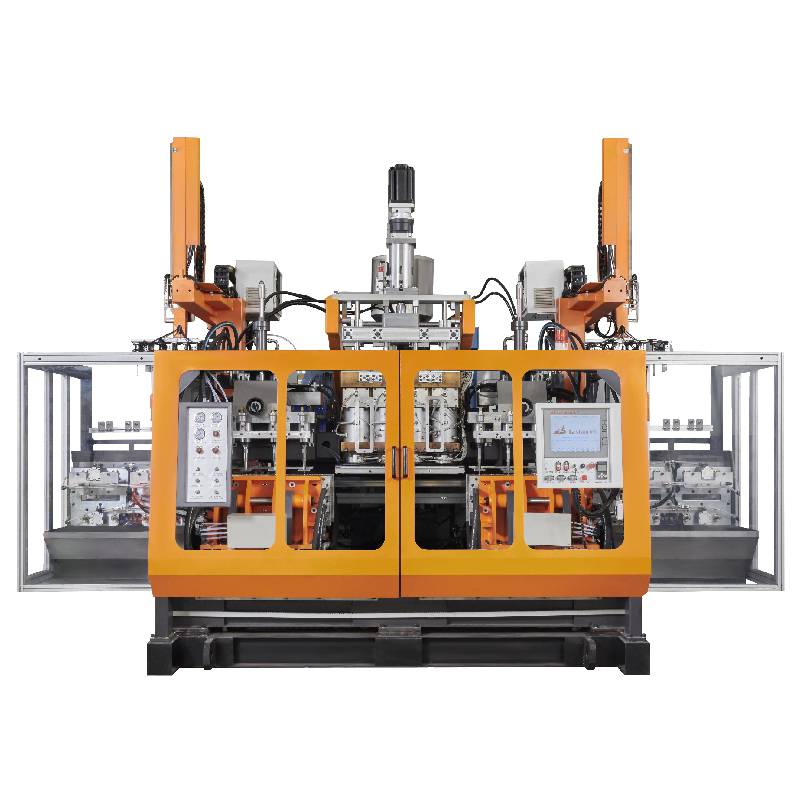

U Linear Hydraulic Toggle System Blow Molding Machine

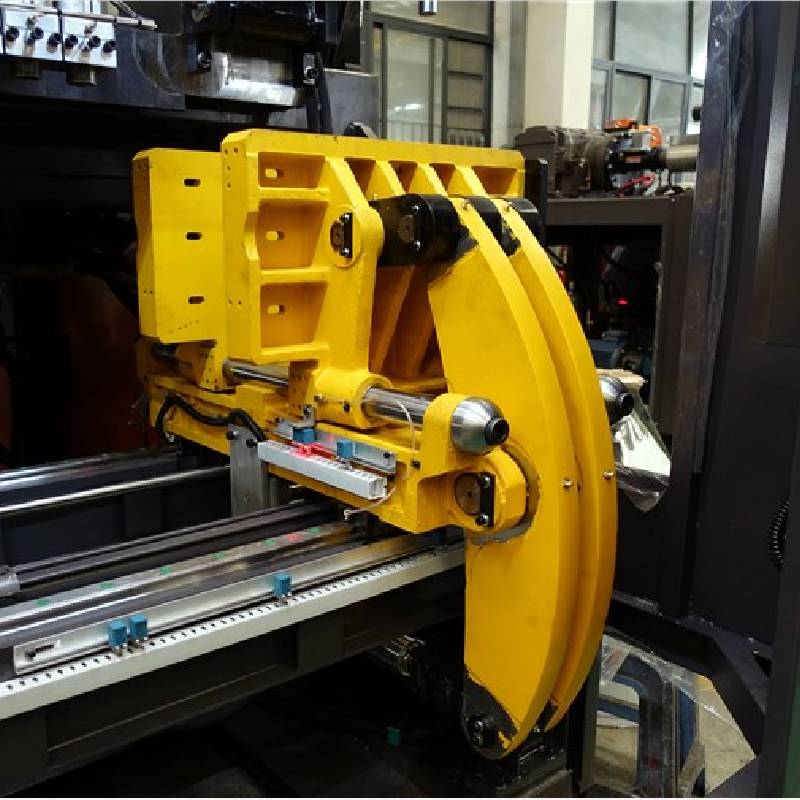

Leshan U series extrusion blow-molding machine is the most mainstream product in the market. U series machines are equipped with the Linear-Line Guide Rail for the smoother and faster motion of the swing frame, which ensures reliable performance and high production capacity. It’s designed for different kinds of plastic bottles such as milk bottles, jerrycan, chemical drums and more. Furthermore, it can work with various auxiliary machines to provide manifold production solutions.

✓Single/Double Station

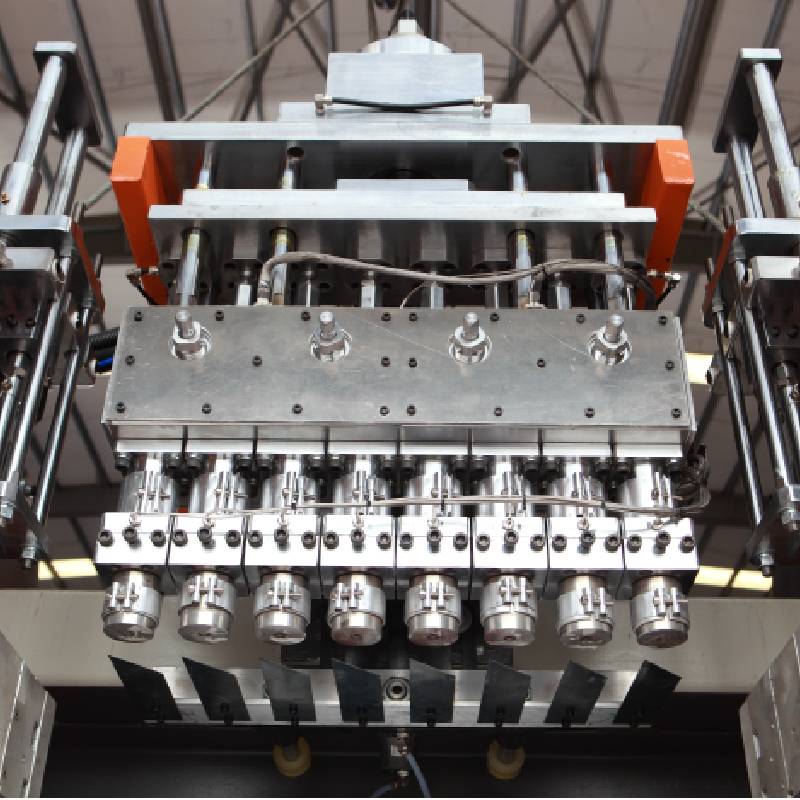

✓Single/Double/Triple/Quadruple..8 Head

✓Production Volume:2ml~30L

✓Multi layers: Co-Extrusion 1-6 Layers

✓Multi cavities: 1~8 cavities

✓Designed for the PE/PP/PETG/PVC/Co-Extrusion material

Category:

U Linear Hydraulic blow molding machine

Tag:

Leshan U Linear Hydraulic Toggle System blow molding machine

Leshan U Linear Hydraulic Toggle System Blow Molding Machine

1.Toggle Balance Clamping System for High Accuracy and Excellent Clamping Force.

2.Servo Hydraulic System includes Servo Head Lifting, Servo Die Head, Servo Parison Control System, Servo Blow Pin, Servo Clamping Unit and Servo Carriage.

3.Linear Rail Electronic Blowing Pin Greatly Increases the Accuracy.

4.Siemens User-Friendly PLC.

5.Low Energy Consumption, Stable, Reliable and Widely Used.

Application

Ball

Bath&Beauty

Beverage Package

Car Supplies

Civil Barrel

Jerry Can

Large-volume Tank

Milk Bottle

Toy

Washing Detergent

Other Type

| EXTRUDER | ||||||||

| Extruder Diameter | mm | 45 | 55 | 65 | 75 | 85 | 90 | 100 |

| Extruder Length/Diameter Ratio | L/D | 21 | 23 | 24 | 24 | 24 | 24 | 27 |

| Extruder Rotating Speed | r/min | 20-40 | 20-40 | 10~48 | 20-78 | 20~67 | 20-66 | 20~66 |

| Max Extrusion Capacity | kg/h | 14 | 25 | 30 | 100 | 130 | 160 | 230/280 |

| Extruder Motor Rated Power | kW | 5.5 | 7.5 | 15 | 30 | 37 | 37 | 75/90 |

| Barrel Heating Zone | / | 3 | 3 | 3 | 3 | 3 | 4 | 4 |

| Barrel Heating Power | kW | 4.5 | 6.2 | 7.2 | 10 | 10.4 | 17 | 17 |

| Cooling Fan Power | kW | 0.04 | 0.08 | 0.12 | 0.3 | 0.54 | 0.72 | 1.85 |

| Die Head | ||

| Cavity number | 1-8 | |

| Twin Cavity Center Distance | mm | 80-280 |

| MOLD PLATEN | 2G | 5G | 5F | 10F | 10G | 10H | 15F | 15G | 20F | |

| Min Clamping Distance Of Mold | mm | 187 | 200 | 230 | 230 | 230 | 300 | 250 | 230 | 380 |

| Max Clamping Distance Of Mold | mm | 335 | 400 | 580 | 620 | 580 | 702 | 650 | 620 | 880 |

| Effective Dimension Of Mold Plate | mm W×H | 380X270 | 480X340 | 300×400 | 380×460 | 600×500 | 480x550 | 600X500 | 750X470 | 480x600 |

| Carriage Stroke | (mm) | 500 | 650 | 500 | 650 | 650 | 650 | 750 | 900 | 700 |

| Clamping Force | kN | 47 | 125 | 80 | 127 | 196 |

| |||